“From simple beginnings to cutting-edge technology, the evolution of AR15 lower receivers has never been more exciting.”

The Origins of AR15 Lower Receivers

The AR15 lower receiver has a rich history that dates back to the 1950s when Eugene Stoner first designed the AR-10 rifle for the Armalite Corporation. The AR-10 was a revolutionary firearm that featured a lightweight aluminum alloy lower receiver, which helped reduce the overall weight of the rifle. This design was later adapted for the AR15, which became the iconic rifle of the United States military.

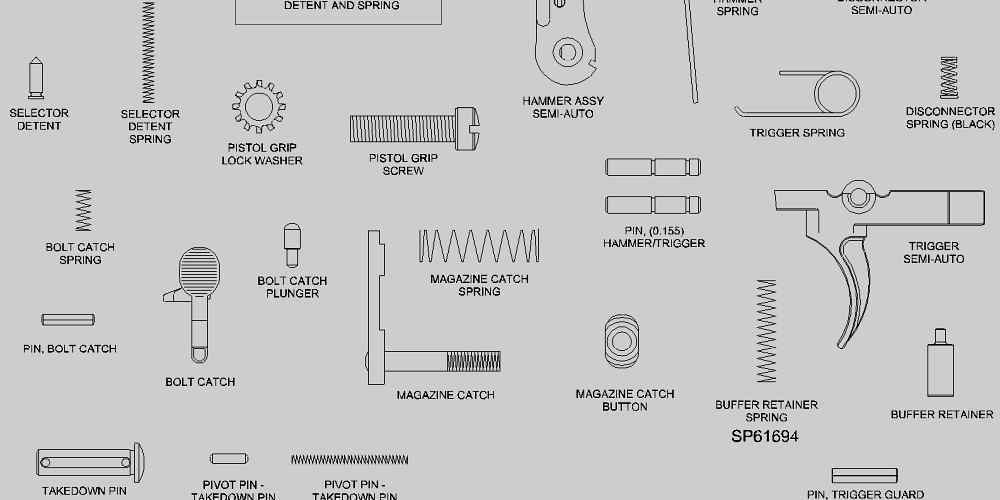

The lower receiver of the AR15 is a critical component of the firearm, as it houses the trigger group, magazine well, and buffer tube. It is also the serialized part of the rifle, meaning that it is the only part that is regulated by the government. Over the years, the design of the AR15 lower receiver has evolved to meet the changing needs of shooters and advancements in technology.

One of the most significant changes to the AR15 lower receiver came in the 1960s when the military adopted the M16 rifle, which was a select-fire version of the AR15. This required modifications to the lower receiver to accommodate the full-auto capability of the rifle. The lower receiver was redesigned to include a third position on the selector switch, allowing the shooter to switch between safe, semi-automatic, and full-automatic fire modes.

In the 1980s, the military adopted the M16A2 rifle, which featured a new lower receiver design with a heavier profile and reinforced areas to improve durability. This design was later adopted for civilian AR15 rifles, as it offered increased strength and reliability over the original design.

In the 1990s, the AR15 lower receiver saw another evolution with the introduction of the A3 flat top upper receiver, which allowed for the mounting of optics and other accessories. This required modifications to the lower receiver to accommodate the new upper receiver design, including a taller rear takedown pin and a modified buffer tube.

In recent years, advancements in materials and manufacturing processes have led to further improvements in the design of AR15 lower receivers. Companies like Aero Precision and Anderson Manufacturing have introduced billet and forged lower receivers made from high-quality aluminum alloys, which offer increased strength and durability over traditional lower receivers.

The introduction of polymer lower receivers has also been a significant development in the evolution of the AR15 lower receiver. Polymer lower receivers are lighter and more affordable than aluminum receivers, making them an attractive option for budget-conscious shooters. However, some shooters have raised concerns about the durability and reliability of polymer lower receivers compared to their aluminum counterparts.

Overall, the evolution of the AR15 lower receiver has been driven by advancements in technology, changes in military requirements, and the needs of civilian shooters. Whether you prefer a traditional aluminum lower receiver or a modern polymer design, there are plenty of options available to suit your needs. The AR15 lower receiver continues to be a critical component of one of the most popular firearms in the world, and its evolution is sure to continue in the years to come.

Changes in Materials and Manufacturing Techniques

The AR15 lower receiver has undergone significant changes in materials and manufacturing techniques throughout its history. Originally designed in the 1950s by Eugene Stoner, the AR15 lower receiver was made from aluminum. This material was chosen for its lightweight properties and durability, making it an ideal choice for military and civilian use.

As technology advanced, manufacturers began experimenting with different materials to improve the performance of the AR15 lower receiver. One of the most significant developments was the introduction of polymer lower receivers. These receivers are made from a lightweight and durable polymer material that offers many advantages over traditional aluminum receivers.

Polymer lower receivers are not only lighter than aluminum receivers, but they are also more resistant to corrosion and wear. This makes them an attractive option for those looking to reduce the overall weight of their AR15 rifle without sacrificing durability. Additionally, polymer lower receivers are often more affordable than their aluminum counterparts, making them a popular choice among budget-conscious shooters.

In recent years, advancements in manufacturing techniques have further improved the quality and performance of AR15 lower receivers. CNC machining has become the standard for producing high-quality lower receivers with tight tolerances and precise dimensions. This method allows for greater consistency and accuracy in the manufacturing process, resulting in lower receivers that are more reliable and durable.

Another innovation in manufacturing techniques is the use of forged lower receivers. Forged receivers are made by hammering a solid piece of aluminum into shape, resulting in a stronger and more durable receiver compared to billet receivers, which are machined from a solid block of aluminum. Forged receivers are often preferred by those looking for a more robust and reliable option for their AR15 rifle.

In addition to changes in materials and manufacturing techniques, the design of AR15 lower receivers has also evolved over time. Modern lower receivers often feature enhanced features such as ambidextrous controls, enlarged trigger guards, and integrated trigger guards. These improvements make the AR15 lower receiver more user-friendly and versatile, catering to the needs of a wide range of shooters.

Overall, the evolution of AR15 lower receivers through history has been driven by a desire to improve performance, durability, and versatility. Advances in materials and manufacturing techniques have led to the development of lighter, stronger, and more reliable lower receivers that meet the demands of today’s shooters. Whether you are a seasoned shooter or a beginner, there is a wide range of AR15 lower receivers available to suit your needs and preferences.

Impact of Military and Law Enforcement Adoption

The AR15 lower receiver has undergone significant evolution throughout history, particularly with the impact of military and law enforcement adoption. These advancements have not only improved the performance and functionality of the AR15 platform but have also influenced the design and manufacturing processes of lower receivers.

One of the key factors driving the evolution of AR15 lower receivers has been the adoption of the platform by military and law enforcement agencies. The AR15 was originally designed for civilian use, but its lightweight and modular design quickly caught the attention of military and law enforcement personnel. As these agencies began to adopt the AR15 for their operations, manufacturers started to develop lower receivers that were more durable, reliable, and compatible with a wider range of accessories.

The military and law enforcement adoption of the AR15 also led to the development of specialized lower receivers for specific applications. For example, some lower receivers are designed to accommodate select-fire or full-auto capabilities, allowing military and law enforcement personnel to switch between semi-automatic and automatic fire modes. Other lower receivers are designed to be compatible with specialized accessories such as grenade launchers, night vision devices, and suppressors.

In addition to specialized lower receivers, military and law enforcement adoption has also driven advancements in materials and manufacturing processes. Early AR15 lower receivers were typically made from aluminum, but advancements in materials science have led to the development of lower receivers made from stronger and lighter materials such as polymer, titanium, and steel. These materials offer improved durability and reliability, making them better suited for the rigorous demands of military and law enforcement operations.

Furthermore, military and law enforcement adoption has also influenced the design of AR15 lower receivers. For example, some lower receivers feature ambidextrous controls, allowing left-handed shooters to operate the firearm more easily. Other lower receivers have integrated trigger guards and enlarged magazine wells, making it easier to manipulate the firearm in high-stress situations.

Overall, the impact of military and law enforcement adoption on the evolution of AR15 lower receivers cannot be overstated. These agencies have driven advancements in materials, manufacturing processes, and design, resulting in lower receivers that are more durable, reliable, and versatile than ever before. As the AR15 platform continues to be adopted by military and law enforcement agencies around the world, we can expect to see further advancements in lower receiver technology that will continue to improve the performance and functionality of this iconic firearm.

Customization and Aftermarket Options

The AR15 rifle has become one of the most popular firearms in the United States, known for its versatility, accuracy, and ease of customization. One of the key components of the AR15 is the lower receiver, which houses the trigger group and serves as the foundation for the rest of the rifle. Over the years, the design and materials used in AR15 lower receivers have evolved, offering shooters a wide range of customization and aftermarket options to suit their needs and preferences.

In the early days of the AR15, lower receivers were typically made from aluminum, specifically 7075-T6 aluminum alloy. This material was chosen for its strength, durability, and lightweight properties, making it ideal for use in firearms. However, as technology and manufacturing processes advanced, new materials such as polymer and titanium began to be used in the production of lower receivers.

Polymer lower receivers offer several advantages over traditional aluminum receivers. They are lighter, more affordable, and can be molded into complex shapes that would be difficult or impossible to achieve with aluminum. Polymer lower receivers are also resistant to corrosion and can be easily customized with different colors and patterns. However, some shooters prefer the rigidity and durability of aluminum receivers, which can withstand more abuse and are less likely to flex or warp under heavy use.

Titanium lower receivers represent the pinnacle of strength and durability in the world of AR15 customization. Titanium is incredibly lightweight, yet stronger than steel, making it an ideal material for high-performance firearms. Titanium lower receivers are also corrosion-resistant and have a distinctive look that sets them apart from traditional aluminum or polymer receivers. However, titanium is also more expensive to manufacture, which can drive up the cost of a custom AR15 build.

In addition to material choices, shooters can also customize their AR15 lower receivers with a variety of aftermarket options. One popular upgrade is the addition of an ambidextrous magazine release, which allows shooters to quickly and easily change magazines with either hand. Another common modification is the installation of an extended trigger guard, which provides more space for shooters wearing gloves or with larger hands.

Other aftermarket options for AR15 lower receivers include upgraded trigger groups, enhanced bolt catches, and custom engraving or laser etching. Shooters can also choose from a wide range of finishes, including anodized, cerakote, and hydro-dipped coatings, to give their rifle a unique look and feel. With so many customization options available, shooters can truly make their AR15 lower receiver their own.

In conclusion, the evolution of AR15 lower receivers has brought about a wide range of customization and aftermarket options for shooters to choose from. Whether you prefer the strength and durability of aluminum, the lightweight properties of polymer, or the high-performance capabilities of titanium, there is a lower receiver out there to suit your needs. With the ability to customize everything from material choice to trigger group upgrades, shooters can truly make their AR15 their own. So, whether you’re a competitive shooter, a hunter, or just a firearms enthusiast, the AR15 offers endless possibilities for customization and personalization.

Legal and Regulatory Developments

The AR15 lower receiver has undergone significant changes throughout its history, both in terms of design and legal regulations. Understanding the evolution of these lower receivers is crucial for gun enthusiasts and collectors alike.

In the early days of the AR15, lower receivers were primarily made of aluminum. This material was chosen for its lightweight properties and durability. However, as technology advanced, manufacturers began experimenting with different materials such as polymer and steel. These materials offered different benefits, such as increased strength or reduced weight, depending on the intended use of the firearm.

As the popularity of the AR15 grew, so did the need for stricter regulations surrounding its components. In the 1980s, the Gun Control Act of 1968 was amended to include restrictions on the sale and transfer of lower receivers. This was in response to the increasing use of AR15s in criminal activities, prompting lawmakers to take action to prevent further misuse of these firearms.

In 1994, the Assault Weapons Ban was enacted, further restricting the sale and transfer of certain firearms, including AR15s. This ban included specific features that were deemed to make a firearm an “assault weapon,” such as a detachable magazine and a pistol grip. Lower receivers that included these features were subject to stricter regulations, making them more difficult to obtain.

However, in 2004, the Assault Weapons Ban expired, leading to a resurgence in the popularity of AR15s. This led to a surge in aftermarket parts and accessories for these firearms, including lower receivers. Manufacturers began producing lower receivers with various features and designs to cater to the growing demand from gun owners.

In recent years, there has been a push for stricter regulations surrounding AR15 lower receivers, particularly in response to mass shootings involving these firearms. Lawmakers have proposed various measures to limit the sale and transfer of lower receivers, such as requiring background checks for all purchases and implementing a registry of all lower receivers.

Despite these challenges, the AR15 lower receiver continues to evolve, with manufacturers constantly innovating to improve the design and functionality of these components. From lightweight polymer lowers to precision-machined steel lowers, there are now more options than ever for gun enthusiasts to customize their AR15s to suit their needs.

In conclusion, the evolution of AR15 lower receivers has been shaped by both technological advancements and legal regulations. Understanding the history of these components is essential for anyone interested in firearms, as it provides valuable insight into the development of one of the most popular rifles in the world. As regulations continue to evolve, it is important for gun owners to stay informed and compliant with the latest laws surrounding AR15 lower receivers.