“Secure your shot, secure your scope – Properly torqued mounts for precision shooting.”

Benefits of Properly Torquing Scope Mounts

When it comes to mounting a scope on your firearm, proper torque is essential for ensuring accuracy and reliability. Many shooters overlook this critical step, but the importance of properly torquing scope mounts cannot be overstated. In this article, we will discuss the benefits of taking the time to torque your scope mounts correctly.

One of the primary reasons why proper torque is crucial when mounting a scope is to prevent damage to your firearm. Overtightening can strip threads or damage the mounting surface, while undertightening can lead to the scope shifting under recoil. By using a torque wrench to apply the manufacturer’s recommended torque settings, you can ensure that your scope is securely mounted without risking damage to your gun.

In addition to protecting your firearm, proper torque also plays a significant role in maintaining accuracy. When a scope is not mounted securely, it can move or shift during recoil, causing your shots to stray off target. By torquing your scope mounts correctly, you can eliminate this potential source of error and improve your shooting consistency.

Properly torquing scope mounts can also help extend the life of your optic. When a scope is not securely mounted, it can experience increased stress and vibrations during shooting, which can lead to premature wear and even damage to the internal components. By ensuring that your scope mounts are torqued correctly, you can help preserve the longevity of your optic and avoid costly repairs or replacements.

Another benefit of properly torquing scope mounts is improved repeatability. When a scope is mounted consistently and securely, you can trust that it will return to zero each time you remove and remount it. This is especially important for shooters who use multiple optics on a single firearm or who frequently travel with their gear. By torquing your scope mounts correctly, you can have confidence that your zero will remain consistent no matter where or when you are shooting.

Proper torque also helps ensure that your scope is aligned correctly with your firearm’s bore. When a scope is not mounted squarely, it can cause parallax errors and impact your accuracy at different distances. By torquing your scope mounts to the correct specifications, you can minimize these alignment issues and achieve more precise shot placement.

In conclusion, taking the time to properly torque your scope mounts is essential for protecting your firearm, maintaining accuracy, extending the life of your optic, improving repeatability, and ensuring proper alignment. By investing in a quality torque wrench and following the manufacturer’s recommendations for torque settings, you can enjoy all of these benefits and more. So next time you mount a scope on your firearm, remember the importance of proper torque – your shooting performance will thank you for it.

Common Mistakes When Torquing Scope Mounts

When it comes to mounting a scope on a rifle, one of the most crucial steps is properly torquing the scope mounts. This step is often overlooked or done incorrectly, which can lead to a host of problems down the line. In this article, we will discuss the importance of properly torquing scope mounts and some common mistakes to avoid.

Properly torquing scope mounts is essential for ensuring that the scope is securely attached to the rifle. If the mounts are not tightened to the correct torque specifications, the scope can become loose during shooting, affecting accuracy and potentially causing damage to the scope itself. Additionally, improper torque can also lead to the scope shifting position over time, resulting in inconsistent shot placement.

One common mistake when torquing scope mounts is over-tightening them. While it may seem like tighter is better, over-tightening can actually cause damage to the scope tube or mount screws. This can result in stripped threads or even a cracked scope tube, rendering the scope unusable. To avoid this issue, always refer to the manufacturer’s specifications for torque settings and use a torque wrench to ensure that you are applying the correct amount of force.

Another mistake that shooters often make is unevenly torquing the mount screws. When mounting a scope, it is important to tighten each screw gradually and evenly to prevent uneven pressure on the scope tube. This can cause the scope to become misaligned or tilted, leading to issues with zeroing and accuracy. To prevent this from happening, tighten each screw a little at a time in a crisscross pattern until all screws are properly torqued.

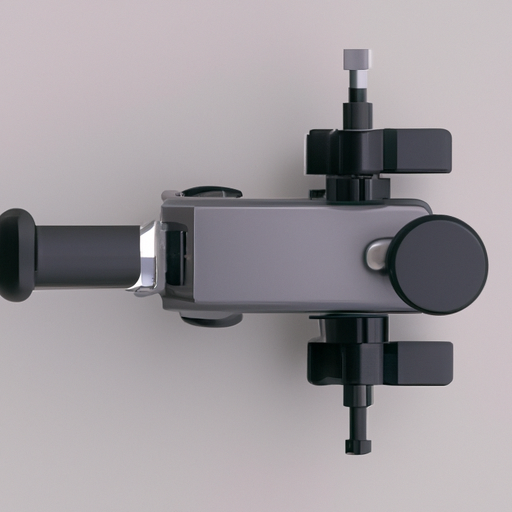

Using the correct tools when torquing scope mounts is also crucial. A torque wrench specifically designed for firearms should be used to ensure that you are applying the correct amount of force. Using a regular wrench or screwdriver can lead to over-tightening or uneven torque, resulting in potential damage to your equipment. Investing in a quality torque wrench will not only help you properly mount your scope but also prevent costly mistakes in the long run.

In addition to using the right tools, it is important to regularly check and re-torque your scope mounts. The recoil from firing a rifle can cause screws to loosen over time, especially if they were not properly torqued initially. By periodically checking and re-torquing your scope mounts, you can ensure that your scope remains securely attached and maintains its zero.

Properly torquing scope mounts may seem like a small detail, but it can have a significant impact on your shooting performance. By avoiding common mistakes such as over-tightening, uneven torque, and using incorrect tools, you can ensure that your scope stays securely attached and maintains its zero over time. Taking the time to properly mount your scope will not only improve your accuracy but also prolong the life of your equipment. So next time you’re mounting a new scope on your rifle, remember to pay attention to proper torque specifications – your shooting results will thank you for it.

Importance of Using a Torque Wrench for Scope Mounts

Mounting a scope on a rifle is a critical step in ensuring accuracy and consistency in shooting. Properly torquing the scope mounts is essential to prevent movement and maintain zero. Using a torque wrench when mounting a scope is crucial for achieving the correct amount of tension without over-tightening, which can damage the scope or the rifle.

One of the main reasons why using a torque wrench for scope mounts is important is to avoid damaging the threads on the screws. Over-tightening can cause the threads to strip, making it difficult to remove or adjust the mounts in the future. This can result in a loose scope that shifts during shooting, leading to inconsistent accuracy and frustration for the shooter.

Additionally, over-tightening can put unnecessary stress on the scope tube, potentially causing it to bend or warp. This can affect the internal components of the scope, leading to poor performance and decreased durability. By using a torque wrench, you can ensure that the scope mounts are tightened to the manufacturer’s specifications, preventing damage and ensuring optimal performance.

Properly torquing scope mounts also helps maintain zero, which is crucial for accurate shooting. If the mounts are not tightened evenly or to the correct torque, the scope can shift slightly each time it is fired. This can result in changes in point of impact and groupings, making it difficult to consistently hit your target. By using a torque wrench, you can ensure that the mounts are secure and will not shift during shooting, allowing you to maintain zero and achieve consistent accuracy.

Another benefit of using a torque wrench for scope mounts is that it helps prevent over-tightening, which can cause stress on the screws and potentially damage them. Over-tightening can lead to shearing or stripping of the screws, making them difficult or impossible to remove. This can be especially problematic if you need to make adjustments or replace the mounts in the future. By using a torque wrench, you can apply just the right amount of pressure to secure the mounts without risking damage to the screws.

In conclusion, properly torquing scope mounts is essential for maintaining accuracy, preventing damage, and ensuring consistency in shooting. Using a torque wrench when mounting a scope allows you to apply just the right amount of tension without over-tightening, protecting both your equipment and your shooting performance. By following manufacturer’s recommendations and using a torque wrench, you can be confident that your scope mounts are secure and your shots will be on target every time.

How Improper Torquing Can Affect Accuracy

When it comes to setting up a rifle for optimal performance, one of the most critical steps is properly torquing the scope mounts. This often overlooked aspect of gun maintenance can have a significant impact on the accuracy of your shots. In this article, we will explore how improper torquing can affect accuracy and why it is essential to pay attention to this detail.

One of the primary ways that improper torquing can affect accuracy is by causing the scope to shift or move during recoil. When a scope mount is not tightened down correctly, it can become loose over time, especially with repeated firing. This movement can lead to inconsistencies in your shots, as the point of impact will shift with each shot. Even a slight movement of the scope can result in missed targets and frustration for the shooter.

Another way that improper torquing can affect accuracy is by putting unnecessary stress on the scope itself. When a scope mount is over-torqued, it can cause damage to the scope tube or mounting system. This can lead to a misalignment of the reticle or even a complete failure of the scope. On the other hand, if the mount is under-torqued, it may not provide enough support for the scope, leading to instability and poor performance.

Properly torquing scope mounts is crucial for ensuring that your rifle is zeroed in correctly. If your mounts are not tightened down to the manufacturer’s recommended specifications, you may find that your zero shifts unexpectedly. This can be frustrating for shooters who rely on consistency in their equipment. By taking the time to properly torque your scope mounts, you can ensure that your zero stays true and that you are hitting your targets consistently.

In addition to affecting accuracy, improper torquing can also impact the longevity of your equipment. Over-tightening or under-tightening scope mounts can cause premature wear and tear on both the mounts and the scope itself. This can result in costly repairs or replacements down the line. By taking care to torque your mounts correctly, you can extend the life of your equipment and save yourself money in the long run.

To ensure that you are torquing your scope mounts properly, it is essential to use a torque wrench. A torque wrench allows you to tighten down your mounts to a specific level of torque, as recommended by the manufacturer. This ensures that you are not over-tightening or under-tightening your mounts and provides a consistent level of tension across all mounting screws.

In conclusion, properly torquing scope mounts is an essential step in setting up a rifle for optimal performance. Improper torquing can affect accuracy, put unnecessary stress on your equipment, and impact the longevity of your gear. By taking the time to torque your mounts correctly using a torque wrench, you can ensure that your rifle is zeroed in correctly, hitting targets consistently, and performing at its best. So next time you are setting up your rifle, don’t overlook this critical step – it could make all the difference in your shooting experience.

Tips for Properly Torquing Scope Mounts

When it comes to mounting a scope on your rifle, one of the most crucial steps is properly torquing the scope mounts. This often-overlooked process can have a significant impact on your shooting accuracy and overall performance. In this article, we will discuss why properly torquing scope mounts is essential and provide some tips on how to do it correctly.

First and foremost, proper torque ensures that the scope is securely attached to the rifle. If the mounts are not tightened to the correct specifications, the scope can move or shift during recoil, leading to inconsistent shot placement. This can be frustrating for any shooter, as it can result in missed shots and wasted ammunition.

In addition to ensuring a secure attachment, proper torque also helps maintain the integrity of the scope and rifle. Over-tightening the mounts can damage the scope tube or strip the threads on the mounting screws, while under-tightening can cause the scope to come loose during use. By torquing the mounts to the manufacturer’s recommended specifications, you can avoid these issues and prolong the life of your equipment.

So, how do you properly torque scope mounts? The first step is to consult the manufacturer’s instructions for your specific scope and mounts. These instructions will typically provide a recommended torque value in inch-pounds or Newton-meters. It is important to use a torque wrench that is calibrated in these units to ensure accurate tightening.

Before attaching the scope, clean and degrease the mounting surfaces to remove any dirt or residue that could interfere with a secure connection. Next, place the scope in the mounts and loosely tighten the screws by hand. Then, use the torque wrench to tighten each screw incrementally in a crisscross pattern until reaching the recommended torque value.

It is important not to exceed the recommended torque value, as this can lead to damage or distortion of the scope tube. Once all screws are properly torqued, check for any movement or play in the scope by gently trying to twist or shift it. If there is any movement, re-torque the screws until secure.

In addition to following these steps, there are a few other tips for properly torquing scope mounts. One common mistake is using too much thread locker on the screws, which can make it difficult to achieve proper torque. Instead, use a small amount of thread locker or anti-seize compound as recommended by the manufacturer.

Another tip is to periodically check and re-torque your scope mounts, especially after heavy use or recoil. Temperature changes and vibrations from shooting can cause screws to loosen over time, so it is important to regularly inspect and maintain your equipment.

In conclusion, properly torquing scope mounts is essential for ensuring accuracy, consistency, and longevity in your shooting setup. By following manufacturer instructions, using a calibrated torque wrench, and periodically checking your mounts, you can avoid common pitfalls and enjoy improved performance on the range or in the field. So next time you mount a scope on your rifle, take the time to properly torque those mounts – your shooting results will thank you!