“Choosing the right case material for optimal performance.”

Importance of Case Material in Revolver Ammunition Selection

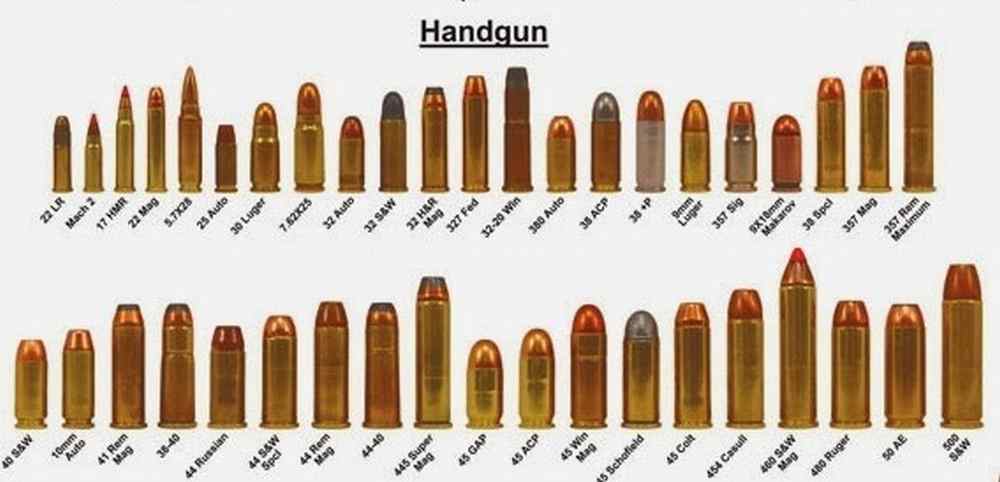

When it comes to selecting ammunition for your revolver, there are many factors to consider. One of the most important aspects to take into account is the material of the cartridge case. The case material plays a crucial role in the performance and reliability of the ammunition, as well as the overall shooting experience. One of the most common materials used for revolver ammunition cases is brass. Brass is a popular choice due to its durability, corrosion resistance, and ease of reloading. Brass cases are known for their ability to expand and contract uniformly when fired, which helps to create a tight seal in the chamber and prevent gas leakage. This results in consistent and reliable performance, making brass-cased ammunition a favorite among shooters. Another popular material for revolver ammunition cases is nickel-plated brass. Nickel-plated cases offer many of the same benefits as brass, such as durability and corrosion resistance, but with the added advantage of a slick surface that aids in feeding and extraction. The nickel plating also provides a distinctive appearance that many shooters find appealing. Steel is another material that is sometimes used for revolver ammunition cases. Steel cases are known for their strength and affordability, making them a good choice for budget-conscious shooters. However, steel cases can be more prone to corrosion and may not expand and contract as uniformly as brass, which can affect the overall performance of the ammunition. Aluminum is a lightweight and cost-effective material that is sometimes used for revolver ammunition cases. Aluminum cases are easy to carry and handle, making them a popular choice for shooters who value portability. However, aluminum is not as durable as brass or steel and may not provide the same level of performance and reliability. Polymer is a relatively new material that is starting to gain popularity in the world of revolver ammunition. Polymer cases are lightweight, corrosion-resistant, and easy to manufacture, making them an attractive option for shooters looking for a modern alternative to traditional metal cases. However, polymer cases may not offer the same level of durability and longevity as metal cases, which can be a concern for some shooters. In conclusion, the material of the cartridge case plays a significant role in the selection of revolver ammunition. Brass and nickel-plated brass are popular choices due to their durability, reliability, and ease of reloading. Steel and aluminum cases offer affordability and portability, but may not provide the same level of performance as brass. Polymer cases are a modern alternative that offers lightweight and corrosion-resistant properties, but may not be as durable as metal cases. Ultimately, the choice of case material will depend on your individual preferences and shooting needs. It is important to consider the pros and cons of each material before making a decision to ensure that you select the best ammunition for your revolver.

Advantages of Brass Cases in Revolver Ammunition

When it comes to selecting ammunition for your revolver, there are a variety of factors to consider. One important aspect to take into account is the material of the case. Brass cases are a popular choice for revolver ammunition for several reasons. In this article, we will explore the advantages of brass cases in revolver ammunition and why they are a preferred option for many shooters. One of the main advantages of brass cases in revolver ammunition is their durability. Brass is a strong and resilient material that can withstand the high pressures generated by firing a round. This durability means that brass cases can be reloaded multiple times without compromising their integrity. This can save shooters money in the long run, as they can reuse their brass cases instead of having to purchase new ammunition each time they go to the range. In addition to their durability, brass cases also offer excellent corrosion resistance. This is important for revolver ammunition, as the rounds are often exposed to moisture and other environmental factors. Brass is highly resistant to rust and corrosion, which helps to ensure that your ammunition will function reliably when you need it most. This is especially important for shooters who store their ammunition for extended periods of time, as brass cases will not degrade or deteriorate over time. Another advantage of brass cases in revolver ammunition is their ability to expand and contract uniformly during firing. This uniform expansion and contraction help to create a tight seal between the case and the chamber, which can improve accuracy and consistency. This is crucial for revolver shooters who rely on their ammunition to deliver precise and consistent performance every time they pull the trigger. Brass cases also offer excellent thermal conductivity, which helps to dissipate heat generated during firing. This can help to prevent overheating of the chamber and barrel, which can lead to malfunctions and reduced accuracy. The thermal conductivity of brass cases also helps to reduce fouling and carbon buildup, which can affect the performance of your revolver over time. Overall, the advantages of brass cases in revolver ammunition make them a popular choice among shooters. Their durability, corrosion resistance, uniform expansion and contraction, and thermal conductivity all contribute to their superior performance in a revolver. Whether you are a competitive shooter, a recreational shooter, or a self-defense enthusiast, brass cases can help to ensure that your revolver ammunition performs reliably and consistently every time you pull the trigger. In conclusion, when selecting ammunition for your revolver, it is important to consider the material of the case. Brass cases offer a number of advantages that make them a preferred option for many shooters. Their durability, corrosion resistance, uniform expansion and contraction, and thermal conductivity all contribute to their superior performance in a revolver. By choosing brass cases for your revolver ammunition, you can ensure that your rounds will function reliably and consistently when you need them most.

Considerations for Steel Cases in Revolver Ammunition

When it comes to selecting ammunition for your revolver, there are a variety of factors to consider. One important consideration is the type of case material used in the ammunition. Steel cases are a popular choice for revolver ammunition, but there are some important things to keep in mind when selecting this type of ammunition. One of the main benefits of steel cases is their durability. Steel is a strong and resilient material that can withstand the rigors of repeated firing without deforming or breaking. This makes steel-cased ammunition a good choice for high-volume shooters who go through a lot of rounds in a single session. Steel cases are also less likely to expand or contract due to temperature changes, which can help ensure consistent performance in a variety of conditions. Another advantage of steel cases is their cost-effectiveness. Steel is generally cheaper to produce than brass, which means that steel-cased ammunition is often more affordable than brass-cased ammunition. This can be a significant factor for shooters who are looking to save money on their ammunition purchases. However, there are some potential drawbacks to using steel-cased ammunition in a revolver. One of the main concerns is that steel cases can be harder on the extractor and other internal components of the revolver. Steel is a harder material than brass, which means that it can cause more wear and tear on the gun over time. This can lead to increased maintenance and repair costs in the long run. Another issue with steel cases is that they are not as flexible as brass cases. Steel does not expand as easily as brass when fired, which can lead to extraction problems in some revolvers. This can result in jams and other malfunctions that can be frustrating for shooters. Despite these potential drawbacks, many shooters find that steel-cased ammunition is a reliable and cost-effective choice for their revolvers. By taking proper care of your gun and using high-quality steel-cased ammunition, you can minimize the risks associated with this type of ammunition. In conclusion, steel cases can be a good choice for revolver ammunition, but there are some important considerations to keep in mind when selecting this type of ammunition. By weighing the benefits and drawbacks of steel cases and taking proper care of your gun, you can ensure that your revolver performs reliably and consistently with steel-cased ammunition.

Impact of Aluminum Cases on Revolver Performance

When it comes to selecting ammunition for your revolver, there are a variety of factors to consider. One important aspect to take into account is the type of case material used in the ammunition. The case material can have a significant impact on the performance of your revolver, so it’s crucial to understand how different materials can affect your shooting experience. One common type of case material used in revolver ammunition is aluminum. Aluminum cases are lightweight and inexpensive, making them a popular choice for many shooters. However, there are some drawbacks to using aluminum cases in revolver ammunition. One of the main concerns with aluminum cases is their durability. Aluminum is a softer metal than brass, which is the traditional material used in revolver ammunition. This means that aluminum cases are more prone to splitting or cracking during the firing process. If a case splits or cracks while in the chamber, it can cause malfunctions and potentially dangerous situations. Another issue with aluminum cases is their ability to expand and contract during firing. Aluminum has a higher coefficient of thermal expansion than brass, which means that aluminum cases can expand more when exposed to high temperatures. This can lead to increased pressure in the chamber, which can affect the performance of your revolver and potentially cause damage to the firearm. Despite these drawbacks, there are some benefits to using aluminum cases in revolver ammunition. As mentioned earlier, aluminum cases are lightweight, which can be advantageous for shooters who are looking to reduce the overall weight of their ammunition. Additionally, aluminum cases are less expensive than brass cases, making them a cost-effective option for shooters on a budget. If you do choose to use aluminum cases in your revolver ammunition, there are some steps you can take to mitigate the potential drawbacks. One option is to use ammunition with a thicker case wall, which can help prevent splitting or cracking. Additionally, you can carefully inspect each round before loading it into your revolver to ensure that there are no visible defects in the case. In conclusion, the case material used in revolver ammunition can have a significant impact on the performance of your firearm. While aluminum cases are a popular choice for their lightweight and cost-effective properties, they do have some drawbacks that shooters should be aware of. By understanding the potential issues associated with aluminum cases and taking appropriate precautions, you can make an informed decision about the best ammunition for your revolver.

Comparing Different Case Materials for Revolver Ammunition

When it comes to selecting ammunition for your revolver, there are many factors to consider. One important aspect to take into account is the material of the case. The case material plays a crucial role in the performance and reliability of the ammunition. In this article, we will explore the different case materials commonly used in revolver ammunition and discuss their pros and cons. One of the most common case materials used in revolver ammunition is brass. Brass is a popular choice due to its durability and ability to expand upon firing, creating a tight seal in the chamber. This expansion helps to prevent gas leakage and ensures consistent pressure levels, resulting in more reliable and accurate shots. Additionally, brass is easy to reload, making it a cost-effective option for shooters who prefer to reload their own ammunition. Another popular case material for revolver ammunition is nickel-plated brass. Nickel-plated brass offers many of the same benefits as standard brass, such as durability and reliability. However, the nickel plating provides an added layer of protection against corrosion, making it ideal for shooters who live in humid or coastal environments. The shiny appearance of nickel-plated brass also makes it easy to identify in low-light conditions, which can be beneficial for quick and efficient reloading. Steel is another common case material used in revolver ammunition. Steel cases are known for their strength and resistance to deformation, making them a popular choice for high-pressure loads. However, steel cases are not as malleable as brass or nickel-plated brass, which can lead to increased wear on the revolver’s chamber. Additionally, steel cases are not as easy to reload as brass, requiring specialized equipment and techniques. Aluminum is a lightweight and cost-effective alternative to brass and steel cases. Aluminum cases are easy to manufacture and dispose of, making them a popular choice for budget-conscious shooters. However, aluminum is not as durable as brass or steel, and may not provide the same level of reliability and consistency in performance. Additionally, aluminum cases are not as easy to reload as brass, as they are more prone to deformation and splitting. Polymer is a relatively new case material that is gaining popularity in the ammunition industry. Polymer cases are lightweight, corrosion-resistant, and easy to manufacture in a variety of colors. However, polymer cases are not as durable as brass or steel, and may not provide the same level of reliability and consistency in performance. Additionally, polymer cases are not as easy to reload as brass, as they are more prone to deformation and splitting. In conclusion, the case material plays a significant role in the performance and reliability of revolver ammunition. Brass and nickel-plated brass are popular choices due to their durability, reliability, and ease of reloading. Steel cases are known for their strength and resistance to deformation, but may cause increased wear on the revolver’s chamber. Aluminum cases are lightweight and cost-effective, but may not provide the same level of reliability as brass or steel. Polymer cases are a newer option that offers corrosion resistance and customization, but may not be as durable or reliable as traditional materials. Ultimately, the best case material for your revolver ammunition will depend on your specific needs and preferences.