“Unlock the secrets to preventing barrel burnout and preserving your wine’s quality.”

Understanding the Chemical Reactions in Barrel Burnout

Barrel burnout is a common issue that many distillers face when aging spirits in barrels. It occurs when the wood in the barrel becomes charred and loses its ability to impart flavor to the spirit. Understanding the chemical reactions that occur during barrel burnout can help distillers prevent this problem and ensure that their spirits age properly.

When a spirit is aged in a barrel, it interacts with the wood through a process called extraction. During extraction, compounds in the wood, such as lignin and hemicellulose, are dissolved by the alcohol in the spirit. These compounds then react with the spirit to create new flavors and aromas. Over time, the spirit becomes more complex and develops a rich, mellow flavor.

However, as the spirit ages, the wood in the barrel can become charred due to the heat and pressure inside the barrel. This charred wood can release compounds such as phenols and tannins, which can overpower the flavors of the spirit and lead to barrel burnout. Additionally, the charred wood can create a layer of carbon on the surface of the barrel, further inhibiting the extraction of flavors from the wood.

To prevent barrel burnout, distillers can take several steps. One important factor is the temperature at which the barrel is stored. High temperatures can accelerate the chemical reactions that lead to barrel burnout, so it is important to store barrels in a cool, dark environment. Additionally, rotating barrels regularly can help distribute heat evenly and prevent hot spots that can lead to charred wood.

Another important factor in preventing barrel burnout is the type of wood used in the barrel. Different types of wood have different levels of extractable compounds, so choosing the right wood for aging spirits is crucial. Oak is the most common type of wood used for aging spirits, as it has a good balance of extractable compounds and imparts a pleasant flavor to the spirit.

Distillers can also prevent barrel burnout by monitoring the aging process closely. Regularly tasting the spirit can help distillers identify any off flavors that may indicate barrel burnout. If barrel burnout is detected, the spirit can be transferred to a new barrel to continue aging without the risk of overpowering flavors.

In conclusion, understanding the chemical reactions that occur during barrel aging can help distillers prevent barrel burnout and ensure that their spirits age properly. By controlling factors such as temperature, wood type, and aging process, distillers can create spirits that are complex, flavorful, and free from the negative effects of barrel burnout. With careful attention to detail and a thorough understanding of the science behind barrel aging, distillers can create high-quality spirits that delight consumers and stand the test of time.

Factors Contributing to Barrel Burnout

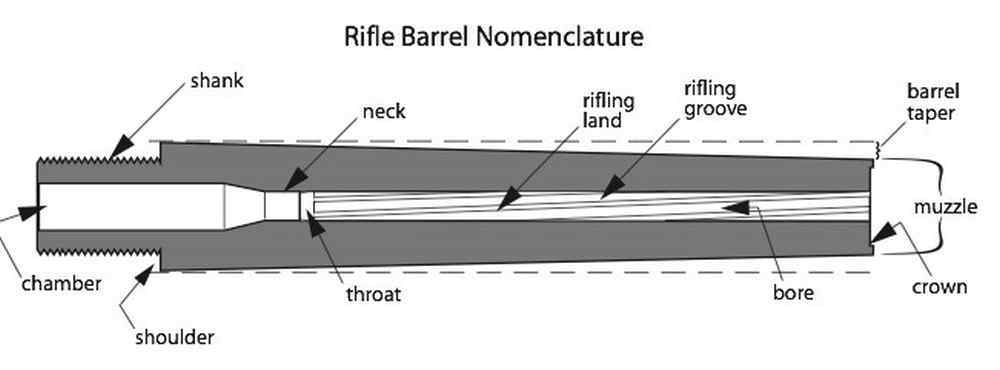

Barrel burnout is a common issue that many shooters face when using firearms. It occurs when the barrel of a gun becomes worn out due to repeated use, leading to decreased accuracy and performance. Understanding the factors that contribute to barrel burnout is essential for gun owners to prevent this issue and prolong the lifespan of their firearms.

One of the main factors that contribute to barrel burnout is heat. When a gun is fired, the barrel heats up due to the combustion of gunpowder. This heat can cause the metal in the barrel to expand, leading to wear and tear over time. The more rounds that are fired in quick succession, the hotter the barrel becomes, increasing the likelihood of barrel burnout.

Another factor that contributes to barrel burnout is the type of ammunition used. Different types of ammunition produce varying levels of pressure and heat when fired. Using high-pressure or high-velocity ammunition can accelerate barrel wear and lead to burnout more quickly than using lower-pressure ammunition. It is essential for gun owners to use the appropriate ammunition for their firearms to prevent barrel burnout.

Additionally, the frequency of use can also contribute to barrel burnout. Shooting a gun frequently without giving the barrel time to cool down between shots can increase the risk of burnout. It is recommended to take breaks between shooting sessions to allow the barrel to cool and prevent excessive heat buildup.

Furthermore, the quality of the barrel itself can impact the likelihood of burnout. Barrels made from high-quality materials and manufactured with precision are less likely to experience burnout than lower-quality barrels. Investing in a well-made barrel can help prevent burnout and ensure the longevity of your firearm.

To avoid barrel burnout, there are several steps gun owners can take. One of the most important things is to properly clean and maintain the barrel after each use. Residue from gunpowder and debris can build up in the barrel, causing increased friction and heat during firing. Regular cleaning with a bore brush and solvent can help prevent barrel burnout and maintain optimal performance.

Additionally, using a barrel cooler or heat sink can help dissipate heat more effectively during shooting sessions. These devices attach to the barrel and help regulate temperature, reducing the risk of burnout. Gun owners can also consider using a barrel wrap or sleeve to insulate the barrel and protect it from excessive heat.

In conclusion, barrel burnout is a common issue that can affect the performance and accuracy of firearms. Understanding the factors that contribute to burnout and taking preventative measures can help gun owners avoid this problem and prolong the lifespan of their barrels. By using the appropriate ammunition, maintaining the barrel properly, and investing in high-quality materials, gun owners can enjoy their firearms for years to come without worrying about barrel burnout.

Techniques for Extending the Lifespan of Barrels

Barrel burnout is a common issue that many distillers and winemakers face when using barrels for aging their products. This phenomenon occurs when the wood in the barrel becomes overused and loses its ability to impart flavor and character to the liquid inside. Understanding the science behind barrel burnout can help you avoid this problem and extend the lifespan of your barrels.

The primary cause of barrel burnout is the extraction of compounds from the wood into the liquid being aged. When a barrel is first filled with a spirit or wine, it begins to extract compounds such as tannins, lignins, and vanillin from the wood. These compounds contribute to the flavor, aroma, and color of the liquid, enhancing its complexity and depth.

However, over time, the wood in the barrel becomes saturated with these compounds, leading to diminished extraction and a decrease in flavor intensity. This is known as barrel burnout. Once a barrel reaches this point, it can no longer effectively age the liquid, and it must be replaced or rejuvenated.

To avoid barrel burnout, it is essential to understand how to properly care for and maintain your barrels. One key factor in extending the lifespan of your barrels is proper cleaning and maintenance. Regularly cleaning and sanitizing your barrels can help prevent the buildup of bacteria and mold, which can accelerate the aging process and lead to burnout.

Another important factor in preventing barrel burnout is proper storage. Barrels should be stored in a cool, dark, and humid environment to prevent the wood from drying out and losing its ability to impart flavor. Additionally, rotating and flipping your barrels periodically can help ensure even extraction and aging, preventing burnout in specific areas of the barrel.

Choosing the right type of wood for your barrels can also help prevent burnout. Different types of wood have varying levels of extractable compounds, with some woods being more prone to burnout than others. Oak is the most commonly used wood for aging spirits and wines due to its high levels of tannins and vanillin, which contribute to rich flavors and aromas. However, other woods such as cherry, chestnut, and acacia can also be used to impart unique characteristics to your liquid.

In addition to proper cleaning, storage, and wood selection, monitoring the aging process is crucial in preventing barrel burnout. Regularly tasting and testing your liquid can help you determine when a barrel has reached its peak extraction and when it is time to replace or rejuvenate it. Keeping detailed records of each barrel’s aging process can also help you track its lifespan and make informed decisions about when to retire or repurpose it.

By understanding the science behind barrel burnout and following these techniques for extending the lifespan of your barrels, you can ensure that your spirits and wines continue to age gracefully and develop complex flavors and aromas. With proper care and maintenance, your barrels can last for many years, providing you with consistent and high-quality products for your customers to enjoy.

Importance of Proper Barrel Maintenance

Barrel burnout is a common issue that many distillers and brewers face when working with barrels for aging their products. This phenomenon occurs when the wood in the barrel becomes overused and loses its ability to impart flavor and character to the liquid inside. Understanding the science behind barrel burnout is crucial for anyone looking to avoid this problem and maintain the quality of their aged spirits or beers.

The primary cause of barrel burnout is the extraction of compounds from the wood into the liquid being aged. When a barrel is first filled with a spirit or beer, the wood imparts flavors such as vanillin, tannins, and lignins to the liquid. Over time, as the liquid interacts with the wood, these compounds are gradually extracted, leading to a decrease in the intensity of flavor in the barrel.

One of the key factors that contribute to barrel burnout is the surface area of the wood in contact with the liquid. The more surface area there is, the faster the extraction process will occur. This is why smaller barrels tend to burn out more quickly than larger ones. Additionally, the type of wood used in the barrel can also affect how quickly burnout occurs. Woods with tighter grain structures, such as oak, tend to release flavors more slowly than woods with looser grain structures.

To avoid barrel burnout, proper maintenance and care of the barrels are essential. One of the most important steps in preventing burnout is to regularly inspect the barrels for signs of wear and tear. Cracks, leaks, or other damage to the barrel can accelerate the burnout process, so it’s crucial to address any issues promptly.

Another key aspect of barrel maintenance is proper cleaning and storage. After a barrel has been emptied, it should be thoroughly cleaned to remove any residual liquid and prevent the growth of mold or bacteria. Storing the barrels in a cool, dark environment can also help slow down the burnout process by minimizing the rate of evaporation and oxidation.

In addition to proper maintenance, there are also some techniques that can be used to extend the life of a barrel and prevent burnout. One common method is to “refresh” the barrel by re-charring or toasting the interior surface. This process can help revitalize the wood and restore some of its flavor-enhancing properties.

Another technique is to “rejuvenate” the barrel by transferring the liquid to a new barrel after a certain period of aging. By moving the liquid to a fresh barrel, you can continue to extract flavors from the wood without risking burnout.

Overall, understanding the science behind barrel burnout and taking proactive steps to prevent it is essential for anyone working with barrels for aging spirits or beers. By properly maintaining and caring for your barrels, you can ensure that they continue to enhance the flavor and character of your products for years to come.

Innovations in Barrel Technology to Prevent Burnout

Barrel burnout is a common issue that many distillers and winemakers face when aging their spirits or wines in barrels. This phenomenon occurs when the wood in the barrel becomes overused and loses its ability to impart flavor and character to the liquid inside. The science behind barrel burnout is complex, but understanding it can help prevent this problem and ensure that your aged spirits or wines are of the highest quality.

Barrel burnout is primarily caused by the extraction of compounds from the wood into the liquid being aged. When a barrel is first filled with spirits or wine, it begins to extract compounds such as tannins, lignins, and vanillin from the wood. These compounds are what give aged spirits and wines their unique flavors and aromas. However, over time, the wood in the barrel becomes saturated with these compounds, leading to a decrease in flavor extraction and ultimately burnout.

One way to prevent barrel burnout is to use high-quality barrels made from the finest wood. Oak is the most commonly used wood for aging spirits and wines due to its ability to impart complex flavors and aromas. However, not all oak barrels are created equal. Barrels made from low-quality wood or improperly seasoned wood are more likely to burn out quickly. By investing in high-quality barrels from reputable cooperages, you can ensure that your barrels will last longer and continue to impart flavor to your aged spirits or wines.

Another factor that can contribute to barrel burnout is the temperature and humidity of the aging environment. Fluctuations in temperature and humidity can cause the wood in the barrel to expand and contract, leading to leaks and loss of flavor extraction. To prevent this, it is important to store your barrels in a controlled environment with stable temperature and humidity levels. This will help maintain the integrity of the wood and prevent burnout.

In recent years, there have been significant advancements in barrel technology aimed at preventing burnout. One such innovation is the use of hybrid barrels, which combine traditional oak staves with alternative materials such as stainless steel or ceramic. These hybrid barrels are designed to prolong the life of the barrel and enhance flavor extraction. By incorporating alternative materials, distillers and winemakers can reduce the risk of burnout and create unique flavor profiles in their aged spirits and wines.

Another innovation in barrel technology is the use of adjustable toasting and charring techniques. Traditional barrel toasting and charring methods involve applying heat to the inside of the barrel to caramelize sugars and release flavor compounds. However, these methods can be inconsistent and lead to burnout. By using adjustable toasting and charring techniques, distillers and winemakers can control the level of heat applied to the barrel, resulting in more consistent flavor extraction and reduced risk of burnout.

Overall, barrel burnout is a common issue that can be prevented with proper care and attention to detail. By investing in high-quality barrels, maintaining a controlled aging environment, and utilizing innovative barrel technology, distillers and winemakers can ensure that their aged spirits and wines are of the highest quality. With a better understanding of the science behind barrel burnout and the latest advancements in barrel technology, you can avoid this problem and create exceptional aged spirits and wines for years to come.