“Unpredictable performance: the hidden danger of inconsistent AR15 ammo brands.”

Manufacturing Processes

When it comes to purchasing ammunition for your AR15, quality is key. However, not all ammo brands are created equal, and some may have inconsistent quality. This can be frustrating for gun owners who rely on their firearms for self-defense, hunting, or recreational shooting. So, why do some AR15 ammo brands have inconsistent quality?

One of the main reasons for inconsistent quality in AR15 ammo brands is the manufacturing process. Each brand may have different manufacturing processes in place, which can lead to variations in the final product. For example, some brands may use lower quality materials or cut corners during production, resulting in ammo that is less reliable and accurate.

Another factor that can contribute to inconsistent quality is the lack of quality control measures in place during the manufacturing process. Some brands may not have strict quality control protocols in place to ensure that each round meets certain standards. This can result in some rounds being over or undercharged, which can affect their performance when fired.

Additionally, the equipment used during the manufacturing process can also play a role in the quality of AR15 ammo. Brands that use outdated or poorly maintained equipment may produce ammo that is not up to par with industry standards. This can lead to issues such as misfires, jams, or inaccurate shots.

Furthermore, the expertise of the personnel involved in the manufacturing process can also impact the quality of AR15 ammo. Brands that employ skilled and experienced workers are more likely to produce high-quality ammunition compared to those that do not invest in training their employees. A lack of knowledge or experience can result in mistakes during production, leading to inconsistent quality.

In order to address the issue of inconsistent quality in AR15 ammo brands, it is important for manufacturers to implement strict quality control measures throughout the manufacturing process. This includes using high-quality materials, maintaining equipment regularly, and providing training for employees. By ensuring that each round meets certain standards, brands can improve the overall quality of their ammunition.

Additionally, brands should also invest in research and development to continuously improve their manufacturing processes. By staying up to date with the latest technologies and techniques, manufacturers can produce ammo that is more reliable and accurate. This can help build trust with consumers and establish a reputation for quality within the industry.

In conclusion, inconsistent quality in AR15 ammo brands can be attributed to various factors, including the manufacturing process, lack of quality control measures, equipment used, and expertise of personnel. By addressing these issues and implementing strict quality control measures, manufacturers can improve the overall quality of their ammunition. Gun owners should do their research and choose reputable brands that prioritize quality to ensure a reliable and accurate shooting experience.

Quality Control Measures

When it comes to purchasing ammunition for your AR15, quality control is a crucial factor to consider. While many reputable brands produce consistent and reliable ammunition, there are some brands that have been known to have inconsistent quality. This can be frustrating for gun owners who rely on their AR15 for hunting, target shooting, or self-defense. So why do some AR15 ammo brands have inconsistent quality?

One of the main reasons for inconsistent quality in AR15 ammo brands is the lack of stringent quality control measures in place during the manufacturing process. Quality control measures are essential for ensuring that each round of ammunition meets the necessary specifications for performance and reliability. Without proper quality control measures, there is a higher likelihood of defects or inconsistencies in the ammunition.

Another factor that can contribute to inconsistent quality in AR15 ammo brands is the use of subpar materials. In order to cut costs, some manufacturers may use lower quality materials in the production of their ammunition. This can lead to issues such as misfires, jams, or inaccurate shots. It is important to choose ammunition from brands that use high-quality materials to ensure consistent performance.

In addition to quality control measures and materials, the manufacturing process itself can also impact the quality of AR15 ammunition. Some manufacturers may rush through the production process in order to meet high demand, leading to errors or inconsistencies in the ammunition. It is important for manufacturers to take their time and pay attention to detail during the manufacturing process to ensure that each round of ammunition meets the necessary standards for quality and performance.

Furthermore, the lack of proper testing procedures can also contribute to inconsistent quality in AR15 ammo brands. Testing is an essential part of the manufacturing process, as it allows manufacturers to identify any issues or defects in the ammunition before it is sold to consumers. Without thorough testing procedures in place, there is a higher likelihood of defects or inconsistencies in the ammunition.

To ensure that you are purchasing high-quality AR15 ammunition, it is important to do your research and choose reputable brands that have a proven track record of consistent quality. Look for brands that have stringent quality control measures in place, use high-quality materials, and have thorough testing procedures to ensure the reliability and performance of their ammunition.

In conclusion, inconsistent quality in AR15 ammo brands can be attributed to a variety of factors, including the lack of stringent quality control measures, the use of subpar materials, rushed manufacturing processes, and inadequate testing procedures. By choosing reputable brands that prioritize quality and reliability, you can ensure that your AR15 performs at its best when you need it most. Remember to always prioritize quality when purchasing ammunition for your AR15 to ensure a safe and enjoyable shooting experience.

Component Sourcing

When it comes to purchasing ammunition for your AR15, quality is key. However, not all ammo brands are created equal, and some may have inconsistent quality. One of the reasons for this inconsistency can be attributed to the sourcing of components used in the manufacturing process.

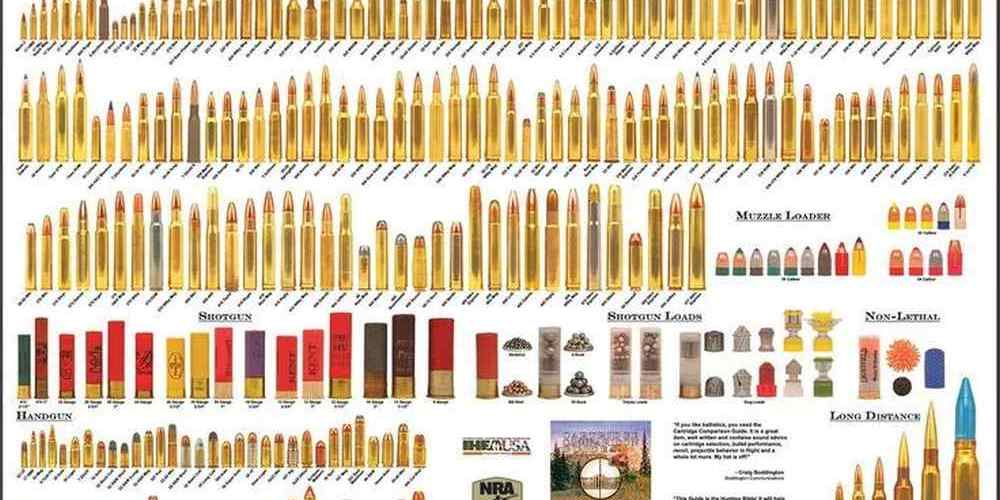

Many ammunition manufacturers rely on a variety of suppliers for components such as brass casings, bullets, and powder. While this can help keep costs down and ensure a steady supply of materials, it can also lead to variations in quality. Different suppliers may have different standards for their components, leading to inconsistencies in the final product.

For example, one supplier may provide brass casings that are slightly thicker or thinner than another supplier’s casings. This can affect the overall performance of the ammunition, as thicker casings may not expand properly upon firing, while thinner casings may be more prone to splitting or cracking. Similarly, variations in the quality of bullets or powder can also impact the accuracy and reliability of the ammunition.

In addition to variations in component quality, differences in manufacturing processes can also contribute to inconsistent ammo quality. Some manufacturers may cut corners or rush production in order to meet demand, leading to subpar ammunition. This can result in issues such as misfires, jams, or inconsistent velocities.

To ensure consistent quality, it is important for ammunition manufacturers to carefully vet their suppliers and maintain strict quality control measures throughout the manufacturing process. This includes testing components for consistency and reliability, as well as conducting thorough inspections of finished ammunition before it is shipped out to customers.

Some ammunition brands may prioritize cost savings over quality, leading them to cut corners when sourcing components or manufacturing their products. While this may help them offer lower prices to consumers, it can also result in inconsistent quality and potentially dangerous ammunition.

In contrast, reputable ammunition brands prioritize quality and reliability above all else. They carefully select suppliers that meet their strict standards for component quality, and they invest in state-of-the-art manufacturing processes to ensure consistency in their products. While this may come at a higher cost to consumers, it also provides peace of mind knowing that the ammunition they are purchasing is of the highest quality.

In conclusion, the sourcing of components plays a crucial role in determining the quality of AR15 ammunition. Variations in component quality, differences in manufacturing processes, and cost-cutting measures can all contribute to inconsistent ammo quality. To ensure consistent performance and reliability, it is important to choose reputable ammunition brands that prioritize quality and reliability in their products. By doing so, you can rest assured that your AR15 is loaded with ammunition you can trust.

Environmental Factors

When it comes to purchasing ammunition for your AR15, consistency is key. You want to be able to rely on your ammo to perform consistently every time you pull the trigger. However, some AR15 ammo brands have been known to have inconsistent quality. There are a variety of factors that can contribute to this inconsistency, including environmental factors.

One of the main environmental factors that can affect the quality of AR15 ammo is temperature. Extreme temperatures, whether hot or cold, can have a significant impact on the performance of ammunition. When ammunition is exposed to high temperatures, the gunpowder can become unstable, leading to inconsistent velocities and pressures. On the other hand, cold temperatures can cause the gunpowder to burn more slowly, resulting in lower velocities and reduced accuracy.

Humidity is another environmental factor that can affect the quality of AR15 ammo. High levels of humidity can cause the gunpowder to absorb moisture, which can lead to misfires and inconsistent performance. Additionally, humidity can cause the brass casing to corrode, which can also affect the reliability of the ammunition.

Altitude is another environmental factor that can impact the quality of AR15 ammo. At higher altitudes, the air is thinner, which can affect the way the gunpowder burns and the pressure inside the cartridge. This can lead to inconsistent velocities and pressures, which can affect the accuracy and reliability of the ammunition.

In addition to temperature, humidity, and altitude, other environmental factors such as air quality and pollution can also affect the quality of AR15 ammo. Pollutants in the air can contaminate the gunpowder, leading to inconsistent performance. Additionally, poor air quality can cause the brass casing to corrode, which can affect the reliability of the ammunition.

To mitigate the impact of environmental factors on the quality of AR15 ammo, it is important to store your ammunition properly. Ammunition should be stored in a cool, dry place away from direct sunlight and moisture. Additionally, it is important to store your ammunition in airtight containers to protect it from pollutants in the air.

When purchasing AR15 ammo, it is also important to consider the reputation of the brand. Some brands have a reputation for producing high-quality, consistent ammunition, while others may have a history of inconsistency. Researching the brand and reading reviews from other shooters can help you make an informed decision when purchasing ammunition for your AR15.

In conclusion, environmental factors can have a significant impact on the quality of AR15 ammo. Factors such as temperature, humidity, altitude, and air quality can all affect the performance of ammunition. By storing your ammunition properly and choosing a reputable brand, you can help ensure that your AR15 ammo performs consistently every time you pull the trigger.

Storage and Handling Practices

When it comes to purchasing ammunition for your AR15, quality is key. However, some shooters may have noticed that certain brands of AR15 ammo can have inconsistent quality. This can be frustrating and even dangerous, as unreliable ammunition can lead to malfunctions and potentially dangerous situations. So, why do some AR15 ammo brands have inconsistent quality?

One factor that can contribute to inconsistent quality in AR15 ammo is the storage and handling practices of the manufacturer. Ammunition is a delicate product that can be easily affected by environmental factors such as temperature, humidity, and exposure to light. If a manufacturer does not store their ammunition properly, it can lead to degradation of the components and ultimately affect the performance of the ammo.

For example, if ammunition is stored in a hot and humid environment, the gunpowder can become unstable and lead to misfires or even catastrophic failures. Similarly, if ammunition is exposed to direct sunlight for extended periods of time, the casing can become brittle and prone to cracking. These storage and handling practices can have a significant impact on the overall quality of the ammunition and can result in inconsistencies in performance.

Another factor that can contribute to inconsistent quality in AR15 ammo is the manufacturing process itself. If a manufacturer cuts corners or uses subpar materials in the production of their ammunition, it can lead to inconsistencies in the final product. For example, if a manufacturer uses low-quality brass casings or improperly measures the gunpowder charge, it can result in variations in pressure and velocity, which can affect the accuracy and reliability of the ammunition.

Additionally, if a manufacturer does not have strict quality control measures in place, it can lead to inconsistencies in the production process. Without proper quality control, there is no way to ensure that each round of ammunition meets the necessary specifications for performance. This can result in some rounds being overcharged, undercharged, or even missing components altogether.

To ensure that you are purchasing high-quality AR15 ammo, it is important to do your research and choose reputable brands that have a track record of consistent quality. Look for manufacturers that have strict quality control measures in place and prioritize proper storage and handling practices. Additionally, consider investing in ammunition that is stored in climate-controlled environments to minimize the risk of degradation.

In conclusion, inconsistent quality in AR15 ammo can be attributed to a variety of factors, including storage and handling practices, manufacturing processes, and quality control measures. By choosing reputable brands that prioritize quality and proper storage practices, you can ensure that you are purchasing reliable and consistent ammunition for your AR15. Remember, when it comes to ammunition, quality is key.